County evaluates pits and quarries, council approves recommendations

Administrator | Mar 16, 2025 | Comments 0

By Sharon Harrison

An evaluation of the County’s pits and quarries, undertaken by the operational services department, was shared with council at Thursday’s committee of the whole meeting, along with staff recommendations, all of which were approved by council.

Staff’s recommendation is to end aggregate licensing for the Sophiasburgh quarry and two pits (Crowe and Cherry Valley). As well, it recommends the Cherry Valley pit, the Crowe pit and the Sophiasburgh quarry be retained and considered for potential excess soil use, with the Sophiasburgh quarry also to be retained for use as a possible organics processing facility, pending completion of a separate feasibility study.

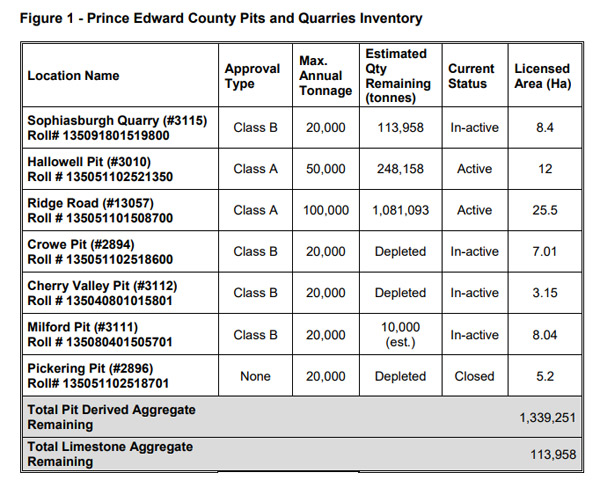

The municipality owns one limestone quarry (Sophiasburgh) and five pits, of which only two are actively operated (Ridge Road and Hallowell pits).

An inventory review of the municipality’s pits and quarry was undertaken to establish available aggregate resources, the current and estimated future aggregate needs, cost to buy versus produce aggregate, and site-specific considerations. It also evaluated potential alternative uses of each property, potential divestment, and recommendations for relinquishing inactive licences.

In his a report, Albert Paschkowiak, environmental services and sustainability supervisor, brought forward several recommendations for council‘s consideration, comprising the complete rehabilitation of three sites: Cherry Valley pit, Crowe pit and the Sophiasburgh quarry. The recommendation includes relinquishing the aggregate extraction licences at each site. All were approved by council.

Staff are also being asked to explore the use of the three sites (Cherry Valley pit, Crowe pit and Sophiasburgh quarry) as excess soils receiving sites, should the sites be retained (following a review of the municipality’s operational needs, to provide costing for this option in advance of the 2026 budget). Council voted to approve the recommendation.

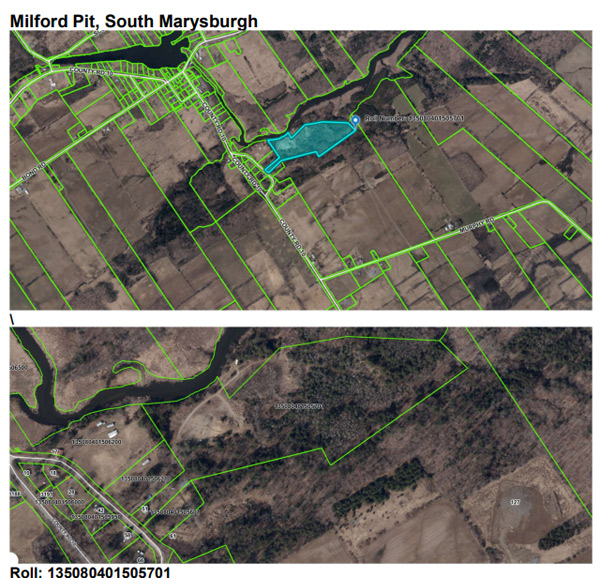

The parcel of land at the Milford pit (Chapmans Crescent) is also being recommended to be declared as surplus, with a staff report to come to include options for divestment or internal use (approved by council).

Details of the County’s pits and quarry, operational status and estimated remaining capacities are shown in the chart (below), where it is noted of the six facilities only the two Ridge Road pits are actively operated. The evaluated list containing more detail can be found at the end of this article.

Speaking to the Milford pit being declared surplus, councillor Brad Nieman noted the report indicates there is some material that is still able to be extracted, and asked how much. Paschkowiak confirmed that the Milford pit has approximately 10,000 tonnes of material left, adding, “That’s a pretty small amount, less than half of a year for the County’s needs.”

Closure of the depleted pits would require a modest amount of rehabilitation and it is anticipated this work could be undertaken in-house by existing staff, equipment and budget, Paschkowiak said. Annual licence fees of $400 are paid to the Ministry of Natural Resources and Forestry each year for each pit. Relinquishing licences on the three depleted or in-active pits and quarries would save approximately $1,200 per year in operational costs.

The County uses three types of aggregate: limestone aggregate, crushed gravel, and sand.

The municipality typically uses tested crushed limestone in the form of ‘granular A’ material for road construction, a material required to achieve the required compaction and other engineering qualities necessary for a well-built road.

“The crushed gravel and sand excavated from municipal pits is not tested and the material is not used for road surface construction,” notes the report. “However, it is suitable for road sub-base, road sanding, general fill and other uses that do not require engineered material.”

Paschkowiak notes the County utilizes approximately 23,000 tonnes of crushed limestone aggregate, which is purchased from a private supplier, and uses 25,000 tonnes of sand material and 2,500 crushed gravel excavated from municipal pits on an annual basis.

“Considering the current aggregates needs and available resources, the County has approximately five years of crushed limestone aggregate remaining at the Sophiasburgh quarry, if extraction were to resume at this location, and 49 years’ worth of sand and crushed gravel aggregate found in the Hallowell, Ridge Road and Milford pits.”

The cost to extract sand and gravel aggregate from a pit is inherently less than producing limestone aggregate from a quarry and costs the municipality approximately $7.92 per tonne, he notes. Extracting sand is also cheaper than purchasing sand, which costs approximately $11 a tonne.

Staff looked at the Sophiasburgh quarry to determine whether it represented the best value for meeting the County’s aggregate needs on the cost to produce aggregate from a municipal quarry versus purchase of limestone aggregate. “Staff are recommending closure of the existing aggregate extraction licence for the Sophiasburgh quarry given the cost to extract the aggregate is more than it costs to purchase.”

“It is estimated that production of aggregate would cost between $11 and $13 per tonne to retain a third-party contractor to clear and grub the area and blast, crush, and screen the material,” outlined the report . “Staff also explored the option of purchasing dedicated equipment for the task which would include a loader, screener, crusher, stacker and scales.”

Capital costs alone would equate to a unit rate of $12.4 per tonne or greater, costs which do not include staff time, fuel, interest on loans to purchase equipment, or any other operational considerations. “Both options represent a relatively expensive and inefficient way of obtaining aggregate compared to purchasing aggregate.”

Currently, the market rate for purchasing aggregate from a private quarry is $9 per tonne, which is the County’s current practice. “Continuing to purchase aggregate from a commercial quarry instead of producing aggregate is anticipated to save between $140,000 and $400,000 over the remaining lifespan of the Sophiasburgh quarry (five years).”

Paschkowiak said, the high cost to prepare municipal aggregate is likely related to the relatively small quantity of aggregate remaining and the high cost to purchase equipment. “Purchasing limestone aggregate may be a cheaper solution as larger commercial operations can take advantage of larger economies of scale to keep their prices low,” he said.

Given that extracting aggregate is not cost effective at the Sophiasburgh quarry, the site could serve a number of other beneficial purposes, to include excess soils storage, an expanded works yard free of limitations associated with an aggregate licence or use as an organics composting facility.

“Given the cost implications, the potential beneficial uses of the site, and the potential cost benefits from converting to excess soils storage, staff are recommending relinquishing the aggregate licence at the Sophiasburgh quarry, but retaining the site and exploring other potential uses.”

Speaking to those pits identified that could accept excess soils, councillor Brad Nieman asked if the County was going accept other soils (not just from local construction projects).

Paschkowiak explained that excess soil are considered to be soils that have been generated on a project that can no longer be re-utilized at that project, where he explained past practices have included taking it to farmers fields or even just disposing at landfills, neither of which are good options, he said.

“Excess soils change with the advent of regulation and that regulation outlines how to re-use that soil beneficially on different types of properties, it outlines different quality standards to set bars for when soils can be used on different properties.”

As part of the evaluation, he said a qualified person would be retained as required by the legislation to create a plan for the County, and as part of that plan for these sites, the option of exploring receiving material outside of the County could be looked at.

“The one caveat that I will put on this that requires more investigation, is that there are exemptions in that regulation for receiving materials that is only from the project, which would be the County. So we want to make sure we explore that, and that will be done as part of the plans that will come forward. “

Nieman also suggested the County consider one site for County excess soil, and two sites for excess soil from outside the County.

“There is lots of construction going on out there, and companies have to try and find locations and sites they can put this to, and some of it they have to travel a long ways to get to that site, which adds cost to the project,” explained Nieman. “If we have a couple sites where we can have that material come in and generate revenue for us to help us offset some of the costs, that’s what we should be doing.”

Paschkowiak said the report will outline possible options going forward for developing these sites as excess soil receiving sites, with one of the requirements to have a fill management plan prepared for each property.

“The fill management plan looks at the property itself, looks at the regulation, and then dictates what can and cannot come to the site. Not all sites are able to receive all types and qualities of soil.”

A fill management plan and registration of the site with the resource productivity and recovery authority would be required to enable the use of the Sophiasburgh quarry as an excess soils receiving site, he said.

The cost to establish the site as an excess soils receiving site is estimated at approximately $20,000, a cost that would be similar to prepare the Crowe and Cherry Valley pits for receipt of excess soils.

“The Sophiasburgh site is estimated to have a capacity of 62,000 cubic meters of space present from past extraction of aggregate,” Paschkowiak confirmed. “Use of this capacity for excess soils of compatible quality could save the municipality on costs to dispose of materials generated from road repair and re-building.”

He said, based on the volume of space available and the typical cost of soil disposal, these costs are estimated between $500,000 and $6,000,000, depending on the quality of the material and the type of material ultimately found to be acceptable at the site.

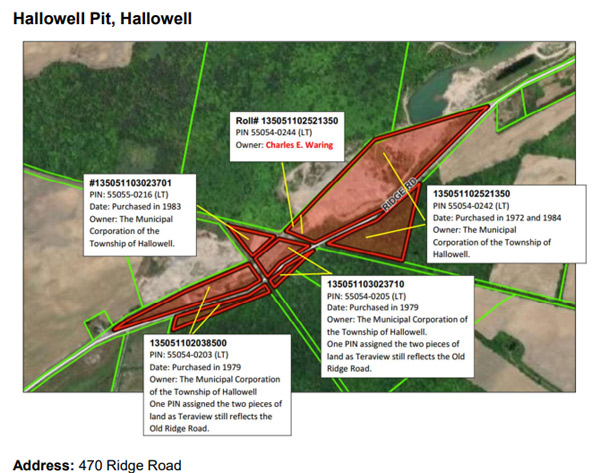

The only two pits owned and operated by the County (470 Ridge Road), provide sand for the majority of the municipality’s operations, as well as a small amount of gravel.

Speaking to the Ridge Road pit, Nieman said the County buys a lot of limestone gravel for road construction, and he wondered if the material from the Ridge Road pit could be used for road bases, something he said he has heard is very good for road base, with better drainage, etc.

“In other municipalities, they screen it and get their winter sand and they have the rock that goes off their screening plant and then they crush out rock and they use that rock for sides of roads or other parts of the road. In order to save on cost of some of these roads that we are doing, can we not use that process?” he asked.

Jeff Bryans, manager of infrastructure, confirmed a lot of the material used from the Ridge Road pit is used, with more and more being used. “We are looking at a more extensive use for a lot of our aggregate at Ridge Road. You can see on a lot of our gravel roads we are using that now because it is a better filtration and it dries quicker, and it allows us to get on the gravel roads quicker to maintain them, so we are looking at all different options right now.”

The Hallowell pit has been mostly depleted with small amounts of aggregate potentially remaining in the south-western, north-western, and central-north parts of the site, outlined Paschkowiak. “The site currently serves to house equipment and stockpiles of material, with future extraction of the remaining material possible.”

Purchased in 2009 from Ridge Road Aggregates (as of the end of 2024, the municipality owes $2,165,421 on the balance of a loan), he notes the Ridge Road pit is located adjacent to and north of the Hallowell pit, where access is provided through the Hallowell pit. It is further noted the northern two-thirds of the Ridge Road pit is zoned environmentally protected.

“Extraction is not possible in this area in accordance with the aggregate extraction licence and a ruling from the Ontario Municipal Board Hearing in 1996,” notes the report. “In 2009, Prince Edward County retained MHBC Planning Urban Design and Landscape Architecture, a private aggregate resource consulting firm, to assess the remaining quantity of material at this pit.”

At the same committee of the whole meeting, council also discussed the evaluation of municipal work-site properties (including some locations mentioned here). Background story below:

Municipal work-site properties evaluated for rehabilitation, expansion or sale

The full list of pits and quarries the County has evaluated, along with staff comments:

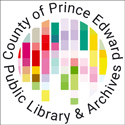

CHERRY VALLEY PIT AND EQUIPMENT DEPOT: Located at 30B Chourney Lane, Cherry Valley (Athol ward), 8.7 acres, zoned institutional (I). Owner: Township of Athol.

CHERRY VALLEY PIT AND EQUIPMENT DEPOT: Located at 30B Chourney Lane, Cherry Valley (Athol ward), 8.7 acres, zoned institutional (I). Owner: Township of Athol.

“The pit was depleted of aggregates several years ago. The zoning of this site is currently institutional and does not allow for further aggregate extraction. The site houses the Cherry Valley works garage, currently used by the green spaces division of operational services. The garage is also used to store equipment for road maintenance and snow plowing. The aggregate licence is still in place at this site.”

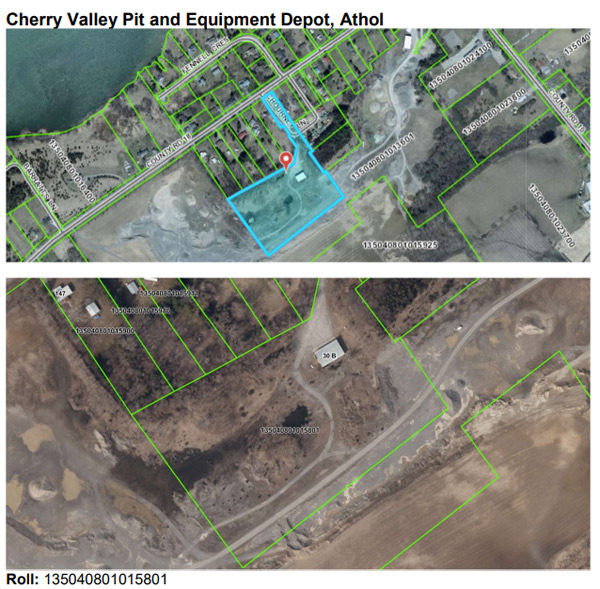

SANDY HOOK WORKS YARD AND CROWE PIT: Located at 75 County Road 1/Sandy Hook Road, Picton (Hallowell ward), 16.69 acres, zoned extractive industrial (MX). Owner : County of Prince Edward.

SANDY HOOK WORKS YARD AND CROWE PIT: Located at 75 County Road 1/Sandy Hook Road, Picton (Hallowell ward), 16.69 acres, zoned extractive industrial (MX). Owner : County of Prince Edward.

This pit was depleted of aggregate many years ago and is currently used to house one of the municipality’s main operational yards. This site houses fuel pumps, a recently constructed coverall for equipment storage, a salt and sand storage dome, a signage shop, and serves as a snow dump in the winter time. The aggregate licence is still in place at this site.

“Staff recommend relinquishment of the aggregate extraction licenses on the Crowe pit and Cherry Valley pit. Both locations are depleted of aggregates and active licences serve no purpose. Divestment, without impacts to municipal operations, is not possible for these two pits given that they also contain works garages. “

It is noted that divestiture of these properties is not recommended without a broader evaluation of municipal operations and alternatives for these locations, the evaluation of which came before council on March 13.

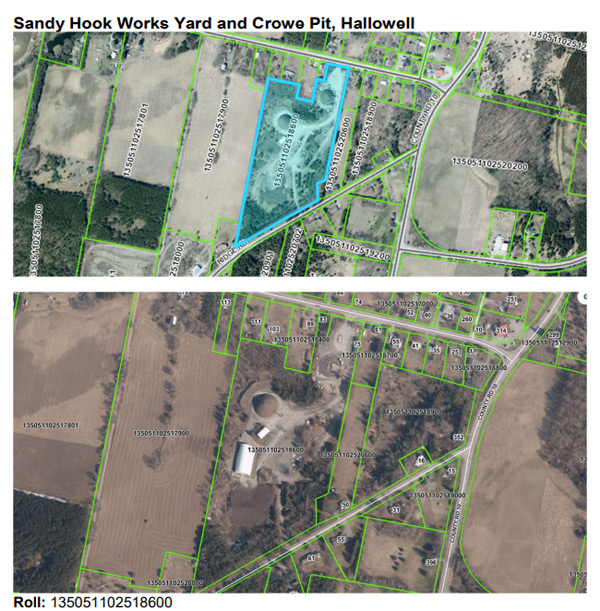

SOPHIASBURGH EQUIPMENT DEPOT, WASTE TRANSFER STATION AND PIT: Located at 35 County Road 14, Demorestville (Sophiasburgh ward), 20 acres approx., zoned general industrial (MG) and extractive industrial (MX). Owner: Municipal corporation of Sophiasburgh.

SOPHIASBURGH EQUIPMENT DEPOT, WASTE TRANSFER STATION AND PIT: Located at 35 County Road 14, Demorestville (Sophiasburgh ward), 20 acres approx., zoned general industrial (MG) and extractive industrial (MX). Owner: Municipal corporation of Sophiasburgh.

Prince Edward County owns one limestone quarry and is located on the same site as the Sophiasburgh waste transfer site, an operations garage, and bylaw’s canine building. The initial quarry was depleted and an amendment to increase the quarry size was filed in 1994. Active extraction has not occurred on this property since approximately 2011, however, the aggregate licence is still in place at the site.

The quarry recently underwent progressive rehabilitation at the request of the Ministry of Natural Resources and Forestry who regulates aggregate extraction sites in Ontario. They identified a large amount of historic excess soils present on the site that would need to be removed if the site were to continue functioning as a quarry. Recently this site was evaluated as a potential site of a proposed organics processing facility.

RIDGE ROAD PIT: Access via 470 Ridge Road, Picton (Hallowell ward), 187.72 acres, zoned extractive industrial (MX) and environmental protection (EP). Owner: County of Prince Edward.

RIDGE ROAD PIT: Access via 470 Ridge Road, Picton (Hallowell ward), 187.72 acres, zoned extractive industrial (MX) and environmental protection (EP). Owner: County of Prince Edward.

Divestment of the Ridge Road pit would negatively impact the municipality’s ability to source its own aggregate and is not recommended.

HALLOWELL PIT: Located at 470 Ridge Road, Picton (Hallowell ward),34 acres, zoned extractive industrial (MX and MX-6) and environmental protection (EP). Owner: County of Prince Edward, and Charles E. Waring (small portion).

HALLOWELL PIT: Located at 470 Ridge Road, Picton (Hallowell ward),34 acres, zoned extractive industrial (MX and MX-6) and environmental protection (EP). Owner: County of Prince Edward, and Charles E. Waring (small portion).

The Hallowell pit has only a moderate amount of aggregate remaining and is actively used as a staging area for extraction operations on the adjacent Ridge Road pit. The Hallowell pit will need to be retained to facilitate current extraction operations. Alternative options to sever a portion of the Hallowell pit may be possible in the future, once the site is depleted of aggregate and further extraction opens up more space on the Ridge Road pit for staging. In the interim, this pit may be considered as a possible excess-soils receiving site in the future should demand require it. A site plan amendment would be required to allow for acceptance of excess soils.

PICKERING PIT: Located at 131 County Road 1/Sandy Hook Road, Picton (Hallowell ward),13.01 acres, zoned extractive industrial (MX). Owner: County of Prince Edward.

PICKERING PIT: Located at 131 County Road 1/Sandy Hook Road, Picton (Hallowell ward),13.01 acres, zoned extractive industrial (MX). Owner: County of Prince Edward.

“This pit was depleted of material and was closed in 2023. This pit has since been converted into an excess soils receiving site to support rehabilitation of the property. A large amount of excess soils generated as part of the municipality’s major road rehabilitation projects are sent to third party receiving sites at additional cost to the municipality.”

Divestment of the Pickering pit is not recommended as it currently functions as the municipality’s only excess soil receiving site.

MILFORD PIT: Located at Chapmans Crescent, Milford (South Marysburgh ward),20 acres, zoned extractive industrial (MX), environmental protection and environmental protection-provincially-significant wetlands (EP and EP-W) – located within the Black Creek forest and marsh an area of natural and scientific interest. Owner: County of Prince Edward.

MILFORD PIT: Located at Chapmans Crescent, Milford (South Marysburgh ward),20 acres, zoned extractive industrial (MX), environmental protection and environmental protection-provincially-significant wetlands (EP and EP-W) – located within the Black Creek forest and marsh an area of natural and scientific interest. Owner: County of Prince Edward.

This pit is not centrally located and comprises a small amount of waterfront property along the Black River in Milford, and is thought to contain a very minor amount of poorly graded sand aggregate and is not actively used. There was some interest from a third party to purchase this property in 2013, however, the pit was retained to support the re-construction of County Road 13. This reconstruction was completed, and no further material is required from the pit.

“The Milford Pit contains very little aggregate (less than one year worth of material) and may be cost prohibitive to reinstate extraction efforts here given the necessary start up costs (clearing and grubbing, mobilization, etc.). The remote nature of the pit also increases trucking costs to move material. The property retains very little value as an excess-soils receiving site given its proximity to water which restricts the quality of soil that could be received there. Given its limited value to operations, staff are recommending the process to declare this property surplus be undertaken.”

The Milford Pit is also located on an Area of Natural and Scientific Interest (ANSI) known as the Black Creek forest and marsh. The official plan recognizes the significance of ANSIs and calls for the highest level of protection. The site’s environmental importance should be considered during the process to surplus, with conditions that eventual use should be consistent with its environmental status.

Filed Under: Featured Articles • Local News

About the Author: